Our Ardent Underground division leverages our world leading expertise to provide shaft construction for underground hydrogen storage. We are a world leader in blind bore shaft drilling with a proven track record in delivering the world’s largest diameter deep shafts.

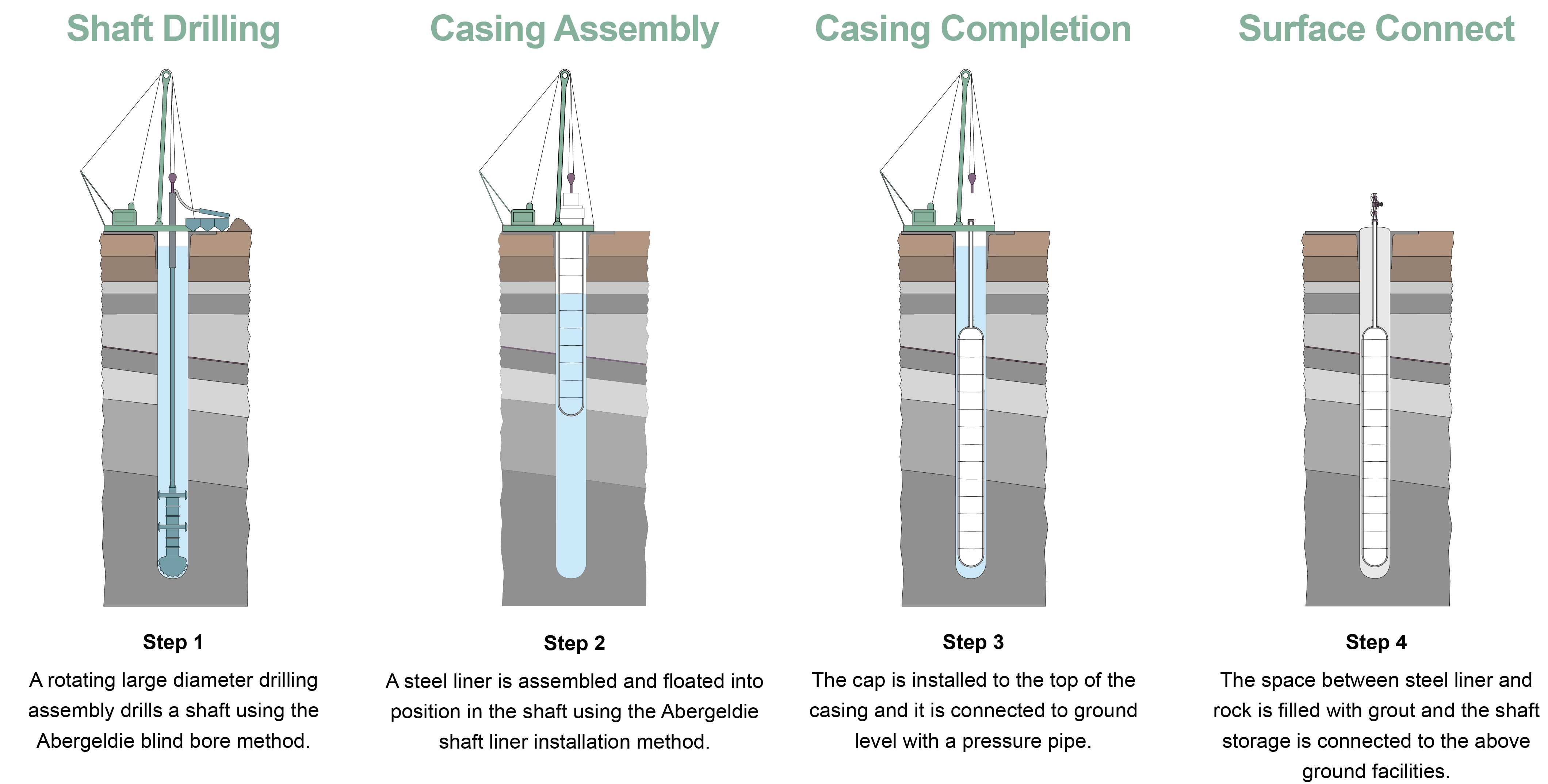

Our blind boring method involves drilling from the surface using a large diameter rotating heavy weighted head that breaks rock using disc cutters similar to those used in tunnel construction. The drilled shaft is maintained full of water during drilling. This allows a positive pressure to be applied to the drilled shaft and for the drill cuttings to be removed through the drill pipe to the surface by reverse circulation.

Blind bore drill rigs

Our fleet of three 450 tonne blind bored rigs were designed and manufactured in-house and have successfully delivered 15 blind bored shafts in Australia over the last 15 years, with shaft depths ranging from 165 metres to 517 metres and finished diameters ranging from 3.5 metres to 6.5m. The majority of the completed shafts have a diameter of around 5m and are drilled to a depth of around 300 metres.

The underground hydrogen storage construction process